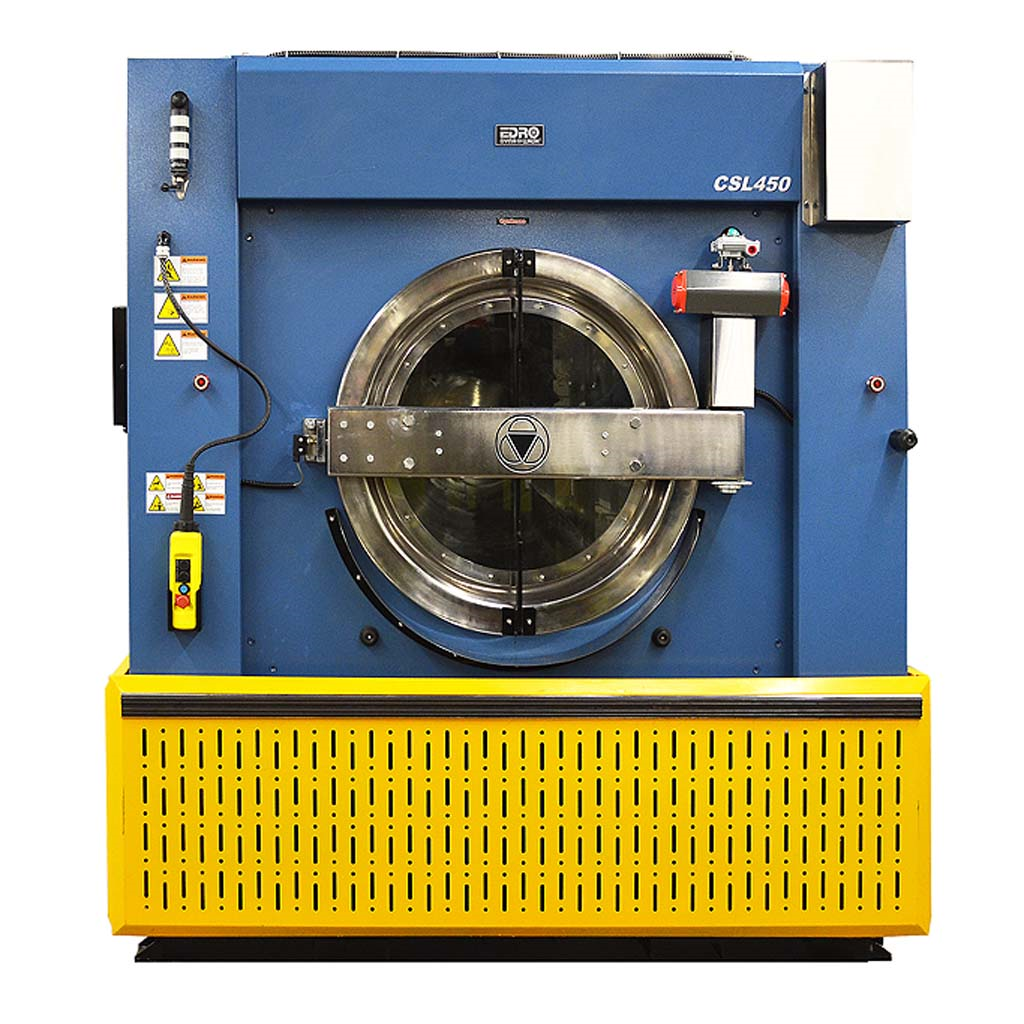

EAST BERLIN, Conn. – The EDRO DynaWash® CSL450 open pocket soft mount tilting washer-extractor features a direct V-belt, inverter with single 50hp motor drive setup, DynaMount shock-and-spring suspension mounting and optional DynOzone – DynaWash® Ozone System.

The DynOzone – DynaWash® Ozone System features Power Cell technology. This revolutionary onboard system is perhaps the most efficient method available to produce and deliver a consistent output of ozone gas to a washer.

The inverter with single-motor drive eliminates 75% of drive components compared to multi-motor/clutch/gear configurations and increases the washer’s available speeds. The programmable inverter-drive inputs can produce a variety of jog, wash, drain, distribution and extract output speeds, allowing the machine to be tailored to exact laundering requirements. The inverter’s soft start reduces amperage demand during starts, stops, acceleration and deceleration, while lowering normal operating running draw.

EDRO’s state-of-the-art DynaTrol touch screen control features Human Machine Interface (HMi) control technology. The unit is coupled with an Electronic Logic Controller (ELC) using ladder logic control code. The new algorithm timing extract step of the ELC software has been updated to give improved conservation efficiency. Unlike conventional rebalancing software technology, the new software allows the ELC code and variable frequency drive to pre-distribute the load more evenly for consistent and uniform extract results. This feature is accomplished through field programmable timing settings of the algorithm extract logic. Fewer imbalances in extract steps mean improved production efficiency through faster cycles and less wear on the machine from potentially damaging out-of-balance vibration. This is a great energy-conscious feature as fewer extract step imbalances mean great water and energy conservation savings. The control features a 50-program memory, and is network capable and field programmable. The control also features advanced troubleshooting debug screens for productivity reporting and maintenance.

For more information visit the company’s web site: EDRO Corporation