By: John Goetz, Global Product Manager, Hydro Systems Company

Loads of Laundry

No hotel guest would be happy with a bath towel that is dirty, stiff, smelly or torn upon check-in. Similarly, a patron at an upscale restaurant would be displeased to find their table linen covered in unsightly stains. Finally, the health and safety of hospital patients can be directly linked to the sanitation of linens. Whether linen is meant to be a bright white or a vibrant color, it’s important for businesses to always present crisp, fresh linen free of stains, odors, tears, bacteria or mold. To accomplish this, textiles must be carefully washed and dried at a well-maintained laundry facility furnished with the appropriate equipment and procedures.

According to the Textile Rental Services Association (TRSA), the U.S. commercial textile service industry processes around 15 billion pounds of laundry annually. About half of this weight is handled by hospitality businesses such as hotels and restaurants. In its On-Premise Laundry (OPL), a hotel may launder a variety of textiles, including bedsheets, towels, tablecloths, napkins and guests’ clothing. In addition to hotels, hospitals, fitness centers and spas, manufacturers and other businesses must also clean textiles. Businesses without an OPL outsource their laundry to large commercial facilities that are equipped with many appropriately sized washers, dryers and downstream equipment like presses and folders.

Professional laundry operations must deal with a wide variety of stains, including marks from dirt, grease, food, drinks, cosmetics, blood and more. With the proper equipment, commercial and industrial laundries can manage up to 100 chemical formulations to thoroughly remove stains on many types of linen. Depending on the type and size of the laundry facility, the chemicals used to tackle stains can represent 17 to 48 percent of annual operating costs, according to research from Kline & Company Inc. Because they handle such an immense volume of textile, and can experience high turnover, it’s important for laundries to implement methods to simplify and improve the laundry process, limit waste, maintain safety and keep costs in line.

The Role of Dispensers

A laundry’s yearly chemical spend can exceed $125,000, according to the study by Kline & Company Inc. Without a reliable chemical dispensing system installed to regulate dosing, costs can easily overwhelm a laundry’s bottom line. For example, when employees must manually measure chemicals, they may use too little, which may not remove linen stains effectively. When a stain remains after a wash, facilities must rewash linen and use stronger, often more expensive chemicals. This increases labor, water and utility costs, and chemical usage, while shortening the life of linen.

On the other hand, if too much chemical is used, laundries are being wasteful and unnecessarily driving up chemical costs. Too much chemical can also damage textiles and require them to be replaced more frequently, adding even more of a cost burden to a laundry operation.

To ensure that the precise amount of chemical is delivered during the wash process, laundries need easy-to-use, automated dosing systems in place. Today, most commercial laundry machines are built with connections for liquid detergents to allow laundry managers to use external chemical dispensing systems. In addition to detergents, dispensers can deliver other chemicals, including de-staining products, alkali boosters, emulsifiers, sanitizers, fabric conditioners and more.

Dispensing systems offer a variety of benefits. For example, they take the guesswork out of chemical dosing by providing the proper measurements each time. They also enhance productivity by reducing the need for rewash cycles. Accurate dosing reduces chemical waste, as well as wasted energy and water, allowing laundries to keep their budgets intact. Intelligent dispensers can utilize the on-board electronics to log and report critical data such as load weight and temperature, chemical usage or load counts. Closed loop systems also maintain employee safety because they reduce the risk of spills or contact with potentially harmful or irritating chemicals. Finally, dispensers help maintain linen quality, and thus brand image.

Selecting a System

Before purchasing a dispensing system, a facility needs to assess its size and needs. Simpler systems, such as a one-detergent push-button system for a single top-load washer, are better suited for very small operations such as an OPL at a bed and breakfast inn.

Medium to large OPLs at bigger hotels and hospitals, which must launder sheets, towels, patient gowns, dining linens and rags, have washer-extractors onsite, which can be 3-30 times larger than a traditional front-loading washer, according to the Alliance for Water Efficiency. These machines will need dispensing systems with more advanced features that can deliver numerous types of chemicals in higher volumes. Traditionally, peristaltic pumps or roller pumps are used in these situations, though increasingly, these operators are more focused on further reducing maintenance, installation and commissioning costs associated with such dispensers.

The largest operations include industrial laundries or linen supply houses. According to TRSA, most of these plants are at least 30,000 square feet in size and can process millions of pounds of laundry every year in huge tunnel washers or multiple large washer-extractors. These sites will need to install larger, central dosing systems that are built to cut costs, drive informed decision-making and ensure reliability.

When looking for a central dosing system for your large laundry operation, there are numerous must-have features and qualities. These include:

· Wireless reporting capabilities. Managers can’t be onsite 24/7, so investing in a smart dispensing system is key. System software and mobile connectivity provides laundry and chemical personnel with a closer look at key performance indicators, like formulas, volume of washes and average production rate. Access to this data allows facility managers to proactively act on issues ranging from inadequate water pressure to staff training opportunities. Remote access capabilities allow certain adjustments to be made even while offsite. This reduces errors that can impact costs and productivity.

· Reliable, durable and accurate diaphragm pumps. Although peristaltic pumps have many advantages including affordability and flexibility, natural deterioration from chemical contact can wear pump tubes down. When pump tubes lose thickness and elasticity over time, this can result in less chemical delivery if they are not regularly replaced and recalibrated, typically every three to six months. All the maintenance costs can add up; for example, a facility using six products across 10 washer-extractors will have 60 tubes. Assuming a total cost of $10 per tube every three months, this equals $2,400 per year to maintain pumps, excluding the downtime, potential to under dispense and additional space required. To avoid accurate dosing and maintenance issues, laundry managers should look for systems that require minimal maintenance.

· Multiple channel configurations. In order to remain productive, facilities that handle a high volume of linen and have numerous washers need a system that can accommodate multiple channel configurations. This enables the system to efficiently dose all products without long queues and prevents expensive delays that can arise if the system is undersized.

· Small, compact design and wall-mount option. Even large or industrial laundries will benefit from a compact and accessible dispenser. Smaller systems that can be mounted to the wall reduce the overall footprint and make installation quick and simple. Plus, it’s easy to locate potential issues and conduct regular maintenance with a single cabinet design.

· Resource-saving capabilities. According to the Kline & Company research, around 60 percent of lodging establishments already have a green laundry program in place. Plus, 95 percent of commercial laundries look for green products and services to appeal to customers. Fortunately, chemical dispensing systems can help laundries further their commitment to the environment. Laundry managers should look for a system that helps save resources like water and energy by reducing rewash rates and measuring water and chemical consumed in the dosing process.

· Manufactured by a trusted company. Look for a chemical dispensing system from a company with a rich history in dosing and dispensing innovation. The manufacturer should be committed to applying technology to improve its designs and have excellent customer service reviews. The provider should also have the expertise to help you select the best chemical dispensing system for your facility’s needs.

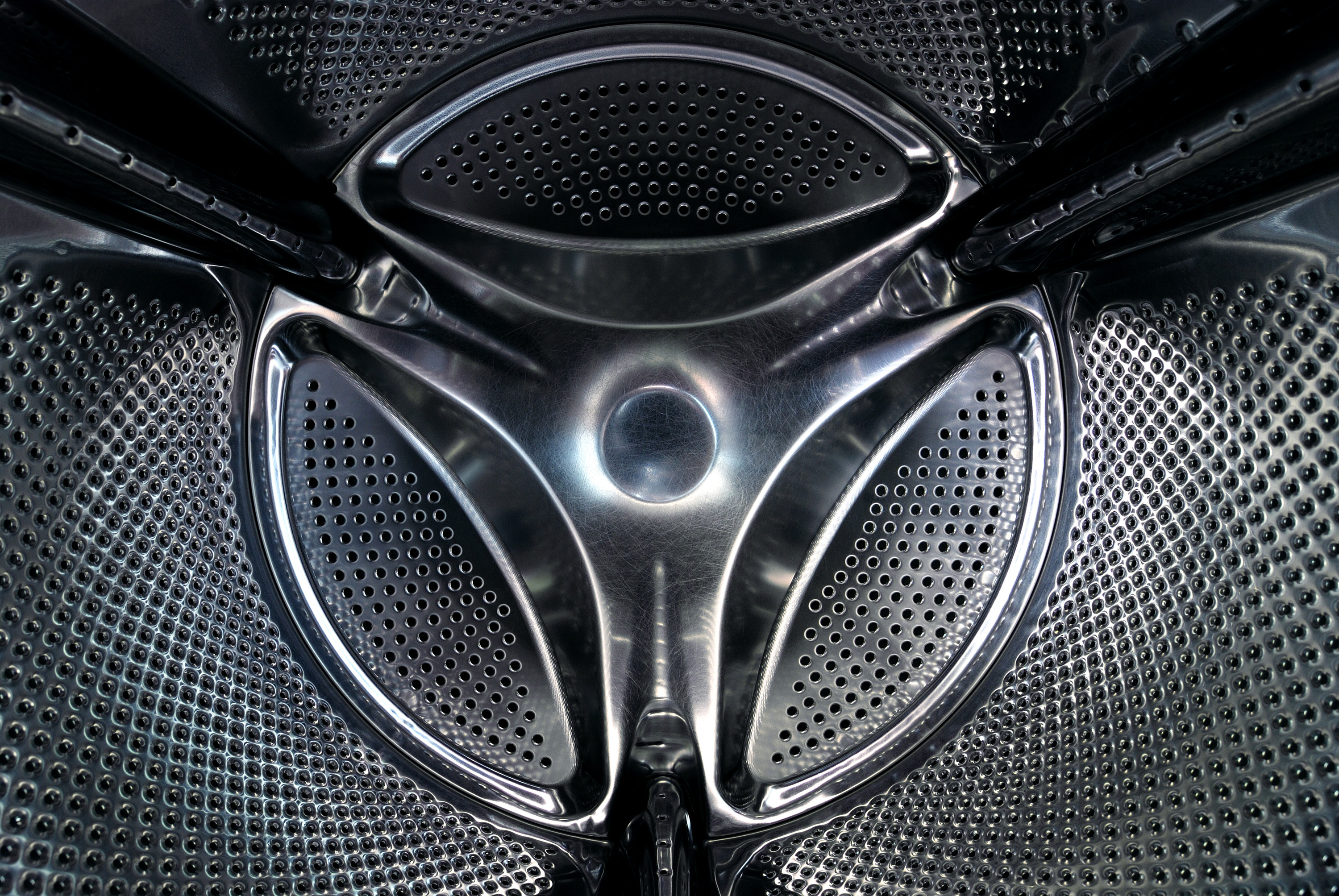

Image above: The Dositec Electromagnetic System features remote monitoring and control capabilities to give customers access to critical chemical data and make adjustments to formulas or settings from anywhere an Internet connection is available. It is designed for smaller laundries with washers below 125 pounds that may not have access to compressed air.

Photo Credit: Can Stock Photo

**Next week in Part 2 of Chemical Dispensing Systems and Choosing the Right One we’ll look at The Future of Laundry**

About the Author

John Goetz is a Global Product Manager for Hydro Systems, an independent manufacturer of chemical injecting, proportioning, dispensing and medicating equipment. He is responsible for the strategic direction, product development roadmap, pricing and P&L of Hydro’s multi-million dollar Laundry & Kitchen dispensing portfolio. For more information, visit http://hydrosystemsco.com/ or contact John at jgoetz@hydrosystemsco.com.