EAST BERLIN, Conn. — Nowadays, hospitals, nursing homes, clean rooms and healthcare environments are faced with ever-increasing exposure to microbiological contamination. The threat of hospital-acquired infection (HAI) – “nosocomial infection” in medical terminology – can also affect the laundry process.

Hospital-acquired infections are a serious threat, so separating soiled, and possibly contaminated, linen from clean linen to avoid cross contamination in the laundry operation is essential.

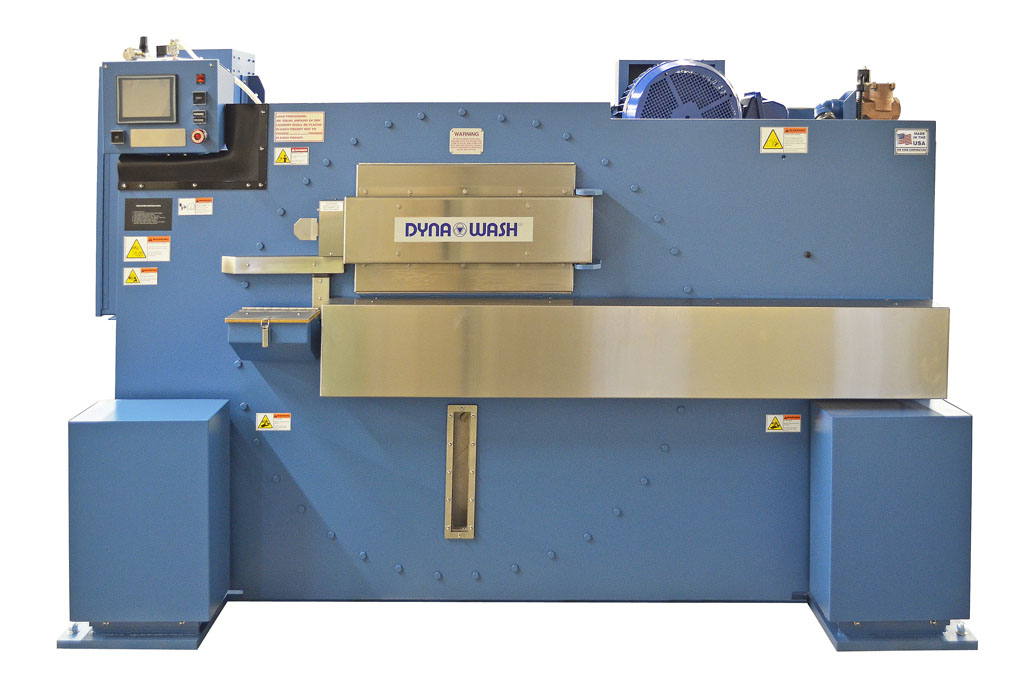

The EDRO DynaWash® Barrier Type PassThru for Clean Rooms washer-extractor is a specialized machine used for the prevention of cross contamination. The washer is loaded from a soiled side and unloaded from the clean room side physically separated by a barrier wall.

The machine is attached to the barrier wall by the “Clean Seal” sealing system. This exclusive system provides a physical barrier and positive air flow between the clean and soiled operating sides.

Built flush against the sides of the Clean Seal, the design provides total separation of loading and unloading operations with better and easier installation. An uninterrupted flow of positive make-up air from the clean room side to the soiled room side is continually flowed through the machine while in operation – thus preventing airborne cross-contamination of the load.

Barrier Type PassThru for Clean Rooms washer-extractors have all the outstanding features that make EDRO washer-extractors extraordinary machines in design, construction and performance.

The built-in DynOzone – DynaWash® ozone system produces a safe, disinfected, and sanitized air stream which is injected into the wash wheel to improve wash quality. The machines also feature state-of-the art DynaTrol HMi Touch Screen Control.

The machines feature the patented “3-D” basket design which assures the ideal wash action for outstanding laundering results, while stainless steel, used for the basket, shaft and shell wrap assure long life.

An interlocking door system prevents both doors from being opened at the same time. A smart control system prevents simultaneous soiled room and clean room operation of the machine. The washer’s control is located on the washroom (loading) side. Forward and reverse jog controls, as well as signal and emergency stop switches are located on the unloading side.

Machine models are available in 100, 150, 200 300 and 400-pound loading capacities.

For additional information, visit the company’s web site at EDRO Corporation