New Perspectives for Mat Laundries, “Pro-Fashional” Garments and Laundry Management – Part III

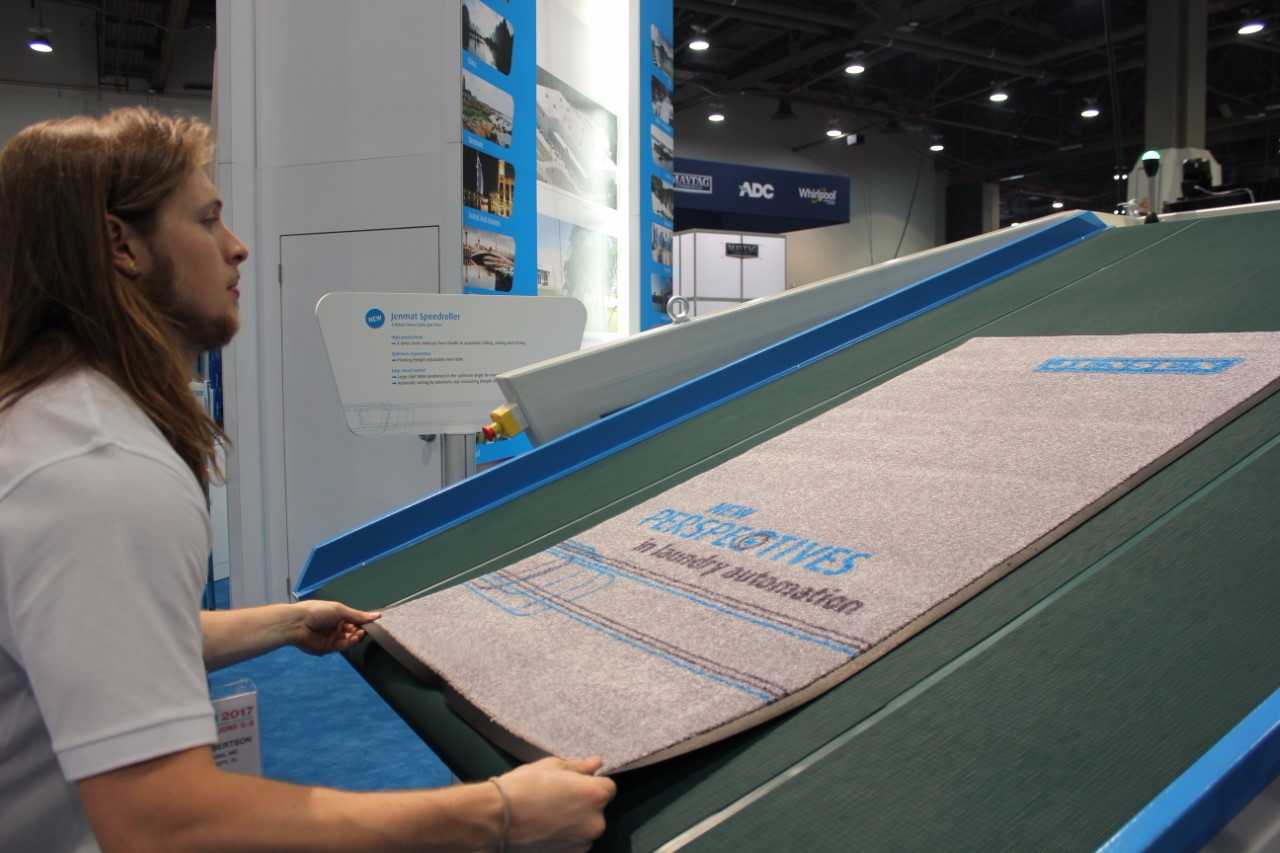

Mat laundries have been trusting JENSEN technology for many decades when setting up the washroom section, with sorting stations, mat shakers, tunnel washers and washer extractors, centrifugal extractors and dryers. Following the company’s promise to be a one-stop-shop supplier, JENSEN now further expands its product offering with finishing equipment for mats. The Jenmat SpeedRoller is capable of rolling up to 500 mats per hour, and automates the mat rolling process at an average speed of 320 mats per hour – that’s four times the performance of one operator in real production. JENSEN has made a significant contribution to the physical health and productivity of the operators that feed the usually quite heavy mats into the roller: The pivoting and height adjustable inlet table makes it a very ergonomic solution, the same applies for the roll-off table. Automatic sorting can be done as well, and in combination the Jenmat roll-off table, mat laundries can now rely on JENSEN technology all the way from the sorting area to the delivery area.

New Perspectives for “pro-fashional” garments

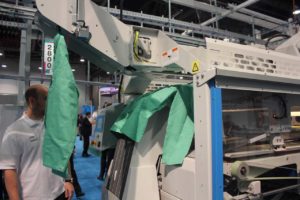

The well-proven Jenfold Butterfly Fox series in combination with the automatic Lobster system hanger, automates the entire work process chain. It is shown in combination with the successful Metricon automated conveyor system that facilitates the transport of garments to the Jenfold Butterfly Fox.

The well-proven Jenfold Butterfly Fox series in combination with the automatic Lobster system hanger, automates the entire work process chain. It is shown in combination with the successful Metricon automated conveyor system that facilitates the transport of garments to the Jenfold Butterfly Fox.

With the new FastFix X, there is no time for downtime. It is a new way of replacing drive dogs within seconds. No tools are required.

The original Metricon® conveyor is a modular system used for automatic handling of washed garments between workstations in a laundry. It is very well proven in use, with more than 500 systems in more than 40 countries – and billions of garments sorted! A Metricon® conveyor system – small or large – is always customized with standard proven components and built to obtain optimum solutions as well as the best possible value. For hanging garment delivery the solution is MetriLink Pro (automatic) or MetriLink Lite (manual) and for folded garment delivery, it is the Lobster hanger together with the Jenfold Butterfly Fox. The system is fully flexible. It can be adapted for any laundry premises and can be expanded easily as the system’s requirements change.

New Perspectives for Laundry Management

By creating solutions today, using tomorrow’s technologies, Globe by Gotli Labs AG leverages the opportunities of the internet of things and offers a unique solution for heavy-duty laundries. Globe – Gotli Labs’ Operational Business Expert offers data recording, production visualization, as well as time recording and planning.

By creating solutions today, using tomorrow’s technologies, Globe by Gotli Labs AG leverages the opportunities of the internet of things and offers a unique solution for heavy-duty laundries. Globe – Gotli Labs’ Operational Business Expert offers data recording, production visualization, as well as time recording and planning.

Globe is the most complete production management information system in the market today: It is the first system that can manage all resources in a laundry – machinery, utilities, energy, as well as staff. The data that have been visualized, documented and analyzed by Globe add to the productivity and availability of the laundry.

“Laundries supplied by JENSEN reach the highest level of labor efficiency in the industry. We were thrilled to present how we live up to our promise to our existing, and future customers” concludes Martin Rauch, JENSEN’s Executive Director for Sales and Innovations.

Learn about JENSEN’s other New Perspectives:

JENSEN’s New Perspectives Part 1 covered Sorting and Handling. It can be found here.

JENSEN’s New Perspectives Part 2 covered the Washroom. It can be found here.

For further inquiries, please contact Gerda Jank, gerda.jank@jensen-group.com

Or, visit the company’s web site: JENSEN