By Al Adcock, Vice President Sales & Marketing, B&C Technologies —

Improving the efficiency of your commercial laundry can often be found in the details of the laundering process itself, receiving, sorting, washing, drying or ironing, and the preparedness and training of the staff.

Efficient washing generally has 4 aspects:

- Temperature

- Time

- Chemicals

- Mechanical Action

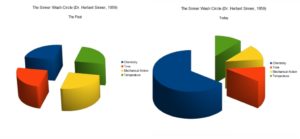

In order to wash at the highest efficiency, all of these factors must be in balance, and this balance has changed since it was developed in 1959 by Dr. Herbert Sinner.

(Click on the image below for details)

- The temperature plays a direct role in removing stains from the laundry, as well as killing germs. Hot water is a better solvent than cold water.

- The washing time is important as too little time in the wash will not allow proper stain removal, while too much time reduces productivity and reduces the life of the goods.

- Chemicals work with the water, and in general are made up of:

- A detergent (containing a surfactant, which lowers the surface tension of the water in effect making it wetter) which attacks and dissolves stains

- A bleach, which whitens fabrics, removes stains, and acts as a disinfectant

- A sour, which is slightly acidic and neutralizes the pH of the bath (improper pH causes yellowing in the dryer)

- A softener, which coats the goods with a thin layer of chemicals that provide lubricating properties and are electrically conductive, making the fabric feel smoother, preventing the buildup of static electricity, increased resistance to stains, and reducing wrinkling and pilling of the fabric. However, fabric softener should never be used if the goods will be processed in an ironer.

- Mechanical action forces the chemical and water solution through the fibers of the fabric, which removes the stain from the fabric, dilutes it, and carries it away.

Next week, Part 2 of Building Efficient Wash Processes in your Commercial Laundry will address the wash program, drying efficiency and operators / maintenance personnel.

************

About the Author:

Al Adcock is VP of Sales and Marketing at B&C Technologies. He is an industry veteran with over 30 years of experience, working for different manufacturers in many different capacities before helping launch B&C Technologies in 2000. Adcock has played an instrumental role in the design of several machines on the market before moving to sales in 2013.

Al Adcock is VP of Sales and Marketing at B&C Technologies. He is an industry veteran with over 30 years of experience, working for different manufacturers in many different capacities before helping launch B&C Technologies in 2000. Adcock has played an instrumental role in the design of several machines on the market before moving to sales in 2013.

Based in Panama City Beach, FL, B&C Technologies is a family-owned customer-focused company that builds the highest quality laundry equipment at the most competitive prices. All B&C equipment relies on engineering-driven designs to produce machines that consistently perform and constantly produce.