Using the latest technologies, Consolidated Laundry Machinery (CLM) promises to increase the production and safety of your mat processing.

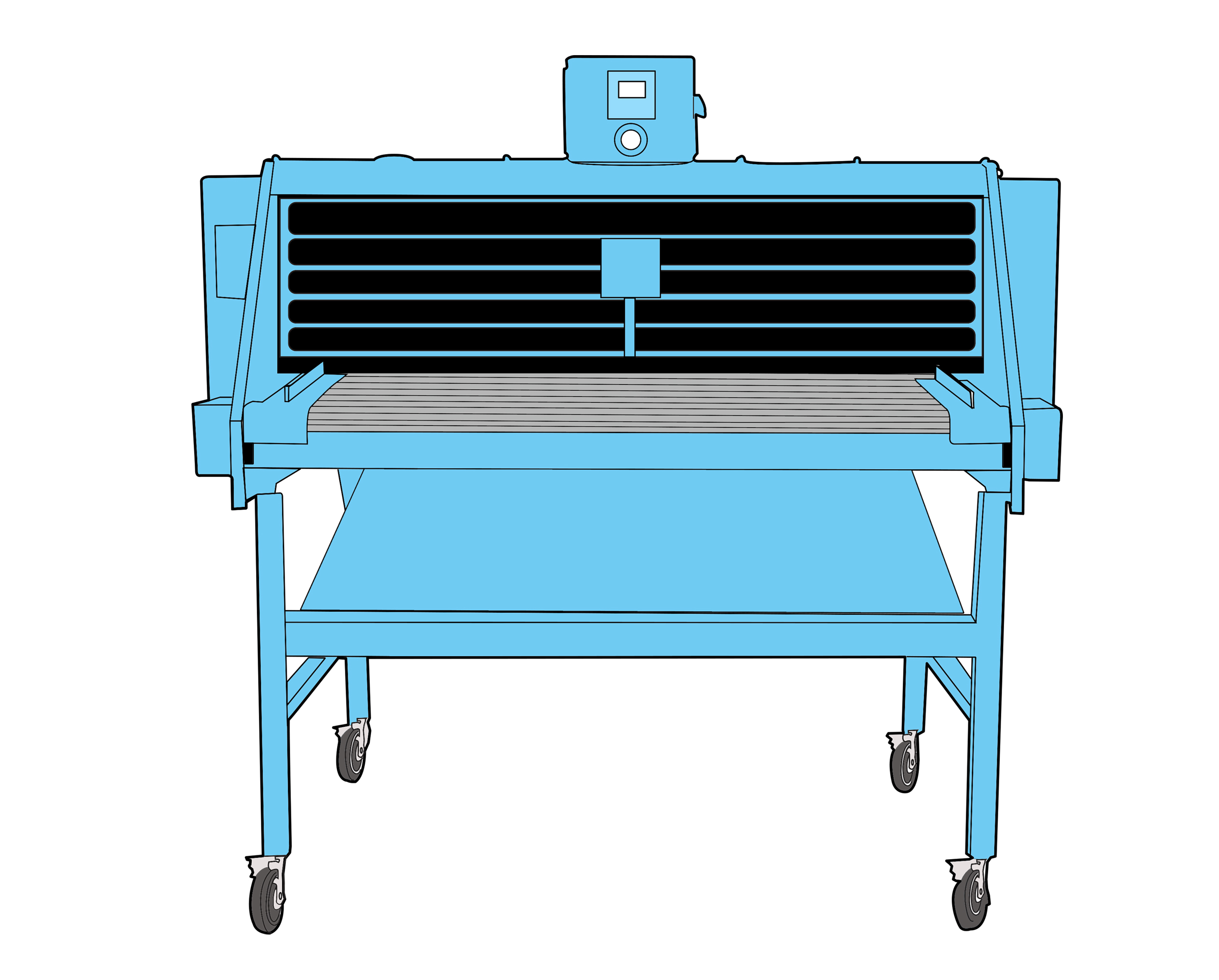

CLM’s Mat Rollers completely automate the mat rolling process. The operator simply places a mat (up to 4’ wide on the MTR-1, up to 5’ wide on the MTR-2) onto the feedboard and the machine automatically takes up the mat, rolls it and drops it into a waiting cart. This leaves the operator free to pick up the next mat, thereby increasing efficiency and overall production.

Two great new features:

- Roll mats with the backing up or down.

- Control the belt automatically or with pedal.

Productivity will increase—the CLM mat roller does the job twice as fast. Your mats are treated well—the unique CLM design keeps mats from being damaged.

Because some of our customers prefer to have the mats returned to the operator, there is also a model that returns the rolled mat to the feeder.

Plant safety is also increased with Mat Rollers from CLM. The seamless feed belt and numerous other safeties reduce the risk of the operator’s clothing being caught in the machine. And because the MTR-1 and -2 perform all movements automatically, the risk of back, neck and repetitive motion injuries is reduced.

All MTRs are PLC controlled, use a standard motor with variable frequency drive so the speed of the machine can be set according to the operator’s proficiency.

For more information: Consolidated Laundry Machinery

Visit CLM at The Clean Show – Booth #1181