By Bill Brooks, North American sales manager for UniMac®

If you haven’t upgraded your equipment recently, old equipment could be costing you big money in repair bills, machine downtime and lost efficiency. Outfitting your laundry facility with energy-efficient equipment with advanced technologies could save you thousands of dollars annually.

In today’s market, you have to own the best to be the best. Here are four benefits of replacing equipment to help you make your on-premises laundry (OPL) more efficient than ever before. Furthermore, doing so can give you total visibility to previously unknown details about the operation, which can help you make adjustments that save even more money in the long-run.

1. Use Less Water and Energy While Ensuring an Optimal Wash

Replacing machines with new washer-extractors that feature as many as 41 programmable wash cycles, including various eco-friendly cycles, will help you conserve water and reduce energy. Precise wash cycles allow you to use the least amount of resources while ensuring the best wash for the type of fabric being laundered. You should also consider a washer with a 400 G-Force extraction speed to remove the maximum amount of water from each load, thus reducing time needed in the dryer and increasing throughput. Using a washer-extractor with a high G-Force extraction rate is the single most effective way to reduce drying times and gas usage, allowing OPL facilities to save on utilities.

Energy consumption can be further reduced by installing energy-efficient tumble dryers with over-dry prevention technology. Tumble dryers account for 70 percent of an OPL’s utility expenses. In fact, over-drying by just eight minutes per load on a 75-pound tumble dryer can cost a facility an extra $883* in utilities and $4,866** in labor annually, according to a UniMac® study. Over-dry prevention technology will shut off the dryer when precise levels of dryness are reached, helping you reduce operating costs and prevent excess utility usage.

Furthermore, with monitoring and reporting tools available on certain machines, you can easily track precisely how much water and energy is being used in the laundry room, enabling you to make adjustments as needed.

Jason Downey has worked in the laundry industry for 10 years. He began his career working in his family’s laundry company, which specialized in green technology. He’s currently a regional sales manager at Southeastern Laundry Equipment Sales, Inc., and has seen firsthand how upgrading to equipment with innovative technologies can help facility managers run a more efficient business.

“In the past, you were never able to see how much water the machine was using, but now you can not only measure water usage, you can also monitor and report on exactly how many cycles ran in a day and how many gallons of water were consumed,” Downey said.

*Based on 10 loads/day, seven days/week and $1.10/therm

**Based on seven days/week and $10/employee hour

2. Unprecedented Control and Reporting Leads to Significant Savings

One of the best ways to ensure a laundry is operating as effectively as possible is through benchmarking. By equipping your OPL with machines featuring advanced controls, cloud-based monitoring and reporting tools, you can get complete visibility to key performance statistics and easy-to-read reports, which can be used to make improvements to the operation.

Advanced control systems and reports are great tools to help you evaluate operational baseline measurements, and improve the factors that contribute to throughput and cost per pound. For example, the time between when washer-extractors stop and the drying process begins can quickly add up. Through benchmarking and reviewing start, stop, and idle times, a manager can make adjustments to staffing to ensure downtime between loads is more efficient. This small change can ultimately reduce labor costs, while processing more loads in a shorter time period. These controls can also document each cycle and highest water temperature with date and time stamps to keep facilities compliant with government standards and assure high-quality results. The result is more accurate output predictions and greater control of the laundry facility.

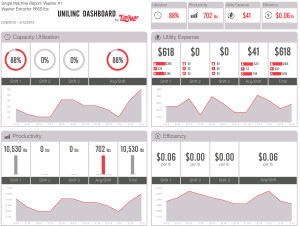

Machines that feature cloud-based monitoring and reporting capabilities make it quick and easy for decision-makers and/or distributors to review data and the factors that impact the cost of operating an OPL. Graphical, executive level dashboard reports can provide real-time information displaying labor, utilities, equipment usage, and the types of cycles being used. Certain systems even organize data from single machines, single locations and multiple locations into separate dashboard reports, making it simple to view information at varied levels of detail.

Accessing this information is also quick and easy. Users can log in to a website from any Internet-connected device to view reports, or elect to receive them via e-mail at designated frequencies for simplified business management. Additionally, laundry managers can grant other decision-makers access to the system, and sign them up to receive performance reports via e-mail periodically, for example monthly, quarterly or bi-annually.

Prior to the advent of control systems that compile machine data into instantly accessible reports, laundry managers and executives did not have visibility to this data that uncovers intricate details about the laundry operation’s efficiency. Monitoring and reporting tools not only make it possible to measure laundry room performance, set benchmarks, and make adjustments that impact the bottom line, but also makes it easy and accessible from anywhere there is an Internet connection.

“Every hotel is basically a living building, and managers are always looking for ways to save money on what it is consuming on a daily basis,” Downey said. “Now, cloud-based monitoring and reporting tools give them a way to do so in the laundry room.”

*****

In part two of Bill Brooks’ article “Four Reasons to Install New Equipment That Puts You in Control,” he will discuss how advanced technologies on new equipment can increase a laundry’s productivity and he will explain how new equipment technologies can preserve linen life and reduce a laundry’s linen replacement costs. Read Part 2 here.

Bill Brooks is the North American sales manager for UniMac(R).

Bill Brooks is the North American sales manager for UniMac(R).