As the government continues to plan and set up field healthcare facilities it is apparent that numerous logistical concerns may be over looked in the rush to add beds in available space for potential patients-Corona related or not.

During my days as a Marine Corps Laundry and Logistics Officer not only did I have responsibility for Field Laundry Units, used in Viet-Nam and other more recent military excursions in other parts of the world. existing laundry and dry cleaning plant operations located on military bases and also laundry facilities located on many Naval ships including hospital ships. During my VA career I had the pleasure to work with many VA design teams who designed the construction of new VA Medical Centers, last count about 40, so logistics and space management were critical.

Recent efforts by FEMA and the Corps of Engineers which were certainly unique really got my attention. Here are a few of the design obstacles that really got my attention as it relates to basic Laundry and Environmental Service Support.

Just like building a new medical facility some concerns regarding the design of temporary medical facilities are as follows, keeping in mind that laundry and EMS support would be appropriately outsourced to the private sector.

Environmental Services (EMS)

1. Space, design and utilities should be allocated to support general housekeeping functions in close vicinity to patient care areas.

2. Storage of supplies that support Housekeeping functions must be allocated to support this activity.

3. Administrative areas must b allocated that support administrative duties required by EMS

4. Toilet, showers, lockers must be designed to support EMS.

5. Design and install emergency showers for EMS and Laundry Personnel.

6. If appropriate designate waste management areas and support facilities.

Laundry

1. Space and design to incorporate linen delivery activities.

2. Access to the structures to support delivery or soiled and clean textiles which includes physical separation of soiled and clean linen delivery activities. (make sure existing loading docks can handle linen delivery (soiled and clean)

3. Clean linen, soiled linen and PPE storage is required to support patient care areas.

“You can have all the beds and patients in the world but if you do not provide logistical support to this activity the operation may fail to achieve the medical goals prescribed.”

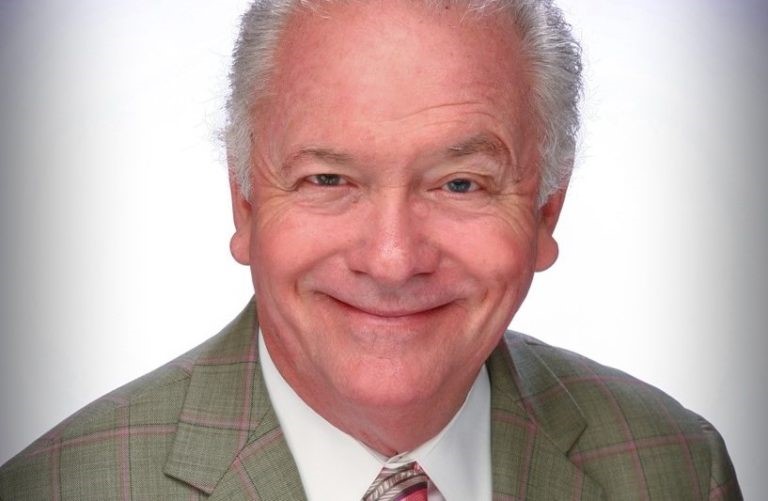

About the Author:

Ken Tyler retired as VP Government Operations in December from Encompass LLC after 15 hears. He also managed the entire textile and laundry operations for the U.S. Department of Veterans Affairs (VA) for 23 years. Prior to that, he was the director of textile and uniform operations for the Department of the Navy, where he was responsible for all fleet and base laundry operations. He retired from the VA in 2000, ending 35 years of government service. Tyler planned and managed the design and construction of 57 VA laundries and he established quality standards for laundry system and textile inspections.