By Gerda Jank, Head of Communications, JENSEN-GROUP

Smart technologies and new materials handling solutions are opening up great new perspectives for heavy-duty laundries. At the JENSEN booth in hall 8, laundry managers from all over the world explored these new perspectives and exchanged ideas with our laundry experts, how JENSEN technology makes laundries fit for a successful future.

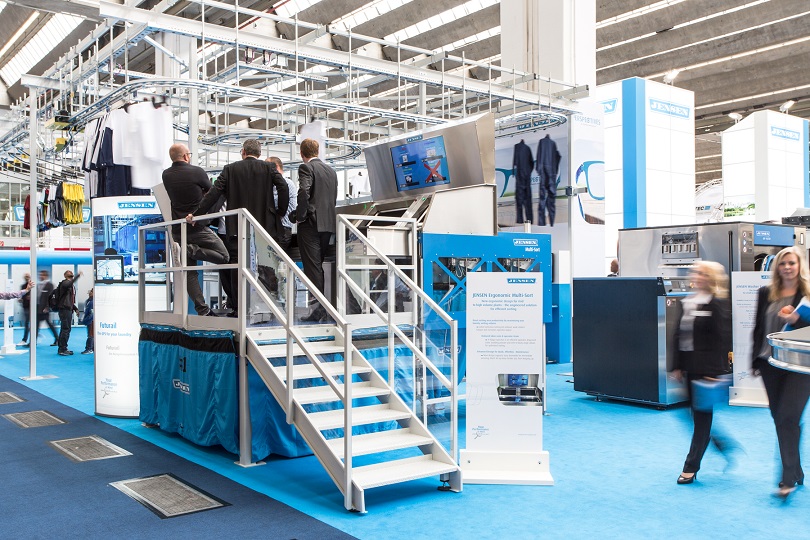

For the first time in our history, we showed a complete laundry at our booth by visualizing the entire flow – including new materials handling solutions, including the unique JENSEN Cockpit system for central production monitoring with real-time information to improve the laundry productivity, and with many great new perspectives for each section of the laundry.

New Perspectives for the sorting & handling area

Get it right from the beginning: Efficient laundry logistics start at the initial point in the laundry where the linen arrives. That’s why JENSEN also invested in new technologies for the sorting and handling area.

The new Ergonomic Multi-Sort platform is the engineered solution for efficient sorting for mid to high volume laundries. Together with the European Work Environment Authorities, this completely redesigned sorting station dramatically increases the productivity by reducing standing posture fatigue and arm to body angle. A healthy and happy operator is an efficient operator: Workplace related illnesses have a major impact on the bottom line. In addition to the direct “cash out” costs like compensation payments, medical expenses and the increase in insurance fee, there are quite a few indirect costs that may not always be properly calculated and considered. The recruiting and replacement costs for instance, the lost productivity and the lower employee morale – which becomes a vicious cycle with an impressive price tag. That’s why more and more laundries have started to introduce a new bottom-line. They look at the eco-social costs and benefits of having clean linen available at the right time, at the right place. At the same time, they also consider the well-being of the people using the linen, and the safety of those processing the linen.

JENSEN also adds a new member to the team in the sorting and handling area. Futurail Buddy is an innovative mobile laundry solution and the laundry’s new “best friend forever”, as complete laundry control has never been easier. This tablet application gives the laundry Manager direct line of sight system control, which exceeds PLC/CE Safety Standards. With single point location maintenance, the material handling can be optimized, while keeping the rest of the plant operational. Futurail has also been upgraded with an enhanced Rail Explorer II software package giving a total systematic overview for all laundry material handling from one centralized location. Rail explorer II provides the ability to monitor individual machine performance and material location in order to optimize efficiency and laundry material in-take and output. Exact product locations can be witnessed on the spot, as well as overall production metrics.

For more information visit the company’s web site: JENSEN-GROUP