GREENSBORO, N.C. — A flatwork ironer safety upgrade kit from laundry product supplier Tingue aims to help flatwork ironer workers by making jammed linen removal safer and easier and assuring that emergency stop bars properly stop the belts when activated.

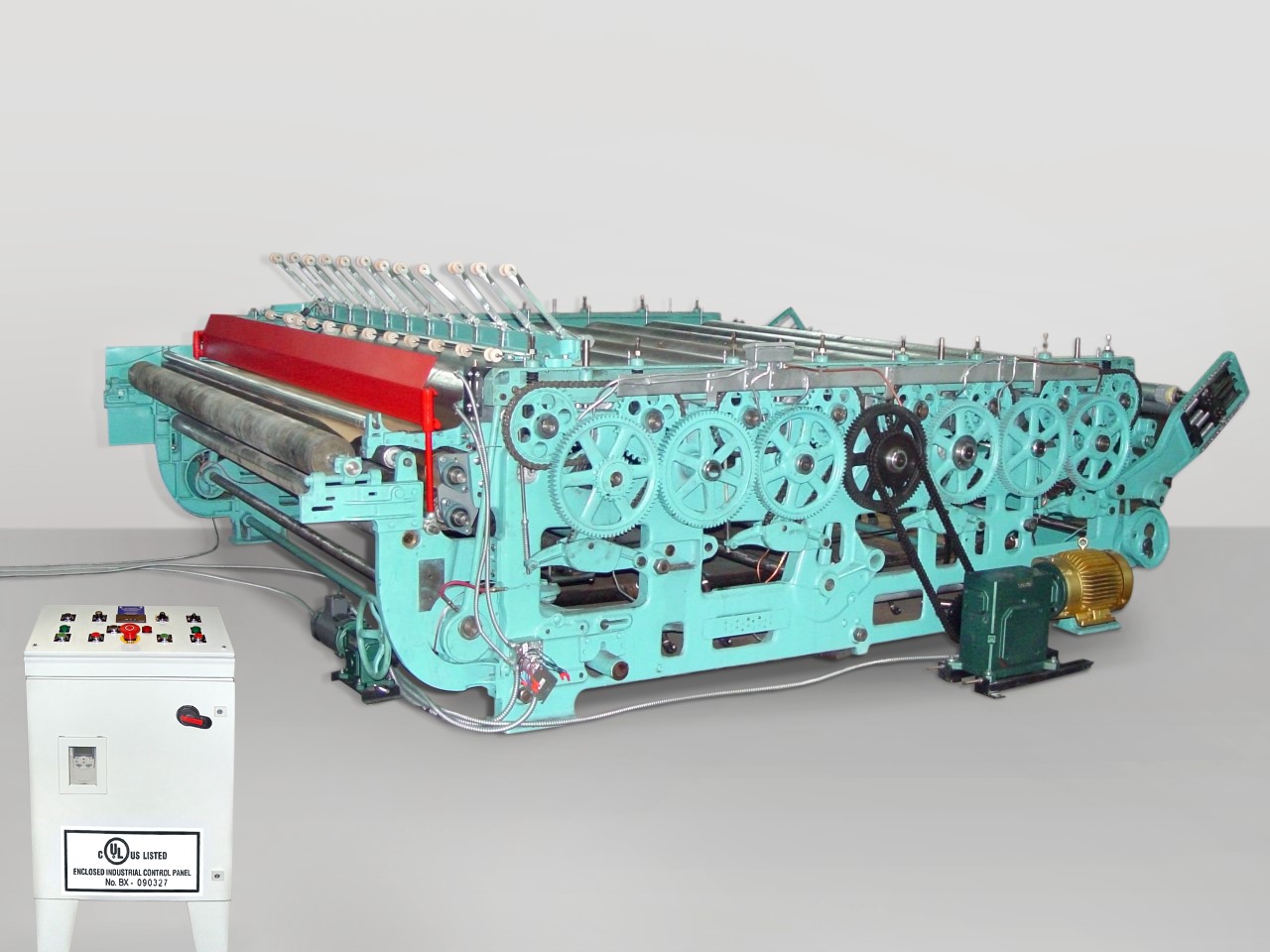

Developed for retrofit on Super Sylon and other American ironers, the flatwork ironer safety upgrade kit integrates the company’s proprietary right hand drive conversion and roll raising rig with its UL-certified inverter cabinet to bring modern safety advances to aging ironers. The right hand drive conversion is programmed to respond instantly to E-stop activation by stopping the feed belts within six inches of travel to support compliance with OSHA standard #1910.262(c)(1) while allowing the machinery to stop with a coasting action that protects the sprockets, chains and other wear parts from damage.

At the flip of a switch, the raising rig raises the ironer rolls to allow jammed linens to be safely and quickly removed. Both the raising rig and right hand drive are controlled via the company’s inverter drive cabinet. Certified by the safety science company Underwriters Laboratories (UL), the inverter drive cabinet meets a growing variety of state mandates requiring electrical installations to meet the rigorous UL standards. The flatwork ironer safety upgrade kit comes complete with the right hand drive, raising rig, inverter drive cabinet, all required motors, chains and other parts, plus easy to follow installation instructions. Tingue also offers full installation services.

For more information, visit the company’s web site: Tingue