To support a growing population of systems and machines in North America, the domestic factory operation of Jiangsu Sea-lion Machinery Co., Ltd., Sea-lion America Company, increases staff to boost sales and technical support, according to a news release.

Team members include:

Aaron Zhang – Executive Deputy General Manager of Jiangsu Sea-lion adds the role of sales consultant to the US office. A graduate of New York University with a Masters in Business Administration, Zhang is responsible for the overseas operations of Sea-lion which currently has sales in 90 countries.

Anderson Zhu – Service Engineer with 16 years’ experience working at Sea-lion including finishing and electrical workshops. Zhu was involved in the research and development, electrical parts assembly and commissioning of Sea-lion’s first tunnel washer system installation over a decade ago. Has numerous Sea-lion project installation experience both domestic and abroad.

Byron Hang – Service Engineer who joined Sea-lion in 2016 with successful tenures in project and electrical design departments, electrical workshop, and intelligent automation department. Hang has dozens of installations and commissioning experience with Sea-lion laundry systems including workshop sorting stations, rail systems, tunnel washer systems, logistical conveyor systems, feeder/ironer/folder

finishing lines, and stand-alone washer/dryer installation and commissioning

“We are pleased to add this talented staff to our operation and be able to offer exceptional local service and support to our customers”, said Ed Kirejczyk, president of Sea-lion America.

Sea-lion is China’s technological leader in heavy-duty industrial and commercial laundry machinery possessing a wealth of experience in manufacturing from years of research and development. With disciplines of automation, washing, finishing and environmental technologies, Sea-lion offers a complete systems approach to high output laundries. Machines are built to world-class quality standards and certified to global standards using first-rate components. Since 1969, Sea-lion has grown into one of the

most respected brands.

The Sea-lion factory campus in Leyu Town, Jiangsu is an impressive, vertically integrated engineering and production facility of over 1.2 million sq.ft. outfitted with the latest manufacturing technologies including solid modeling for all equipment, CNC flame and laser cutters, robotic welders, automated electrostatic painting systems, and a state-of-the-art assembly workshop.

For more information, visit the company’s web site: Sea-lion America

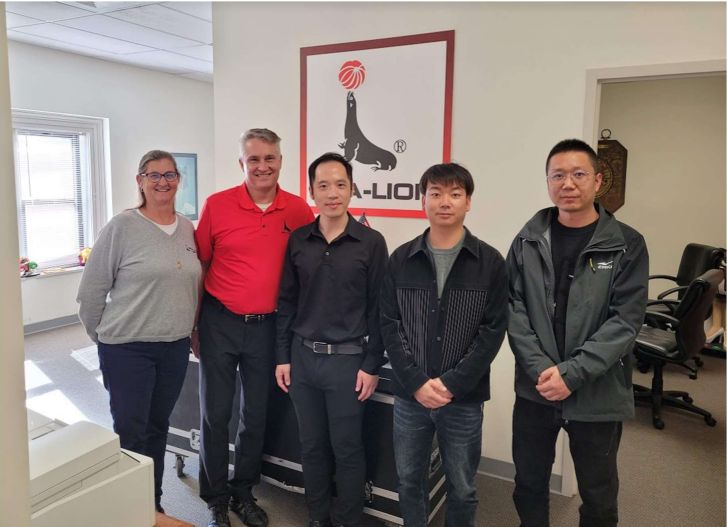

Picture above (L to R): Caroline Wojcicki, Ed Kirejczyk, Aaron Zhang, Byron Hang, and Anderson Zhu