By Al Adcock, VP of Sales and Marketing at B&C Technologies

In our industry, we spend quite a bit of time talking about G-force and how important it is to understand and account for. In fact, there are a few posts dealing with the subject on this very blog. As a companion to G-force, today we’ll talk about moisture retention and how this easy measurement plays into the overall efficiency and throughput of your commercial laundry as well as how it affects the drying and finishing operations as well as larger considerations like linen life.

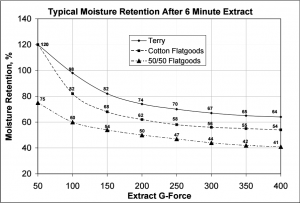

Moisture retention can most easily be described as the water that remains in the goods after the washing process is complete. A typical wash process will wet the goods, apply appropriate chemicals, rinse those chemicals away, and finally extract water from the goods at the end of it all. This final extraction step determines the final moisture retention of the goods and is directly related to the G-force at which the goods were extracted: The higher the extraction force is, the lower the moisture retention. It is important to note that this process is not linear, for example, doubling the G-force won’t automatically halve the moisture retention. For convenience, I’ve included a handy graph below for some typical fabric types (click to see it full sized).

Moisture retention can most easily be described as the water that remains in the goods after the washing process is complete. A typical wash process will wet the goods, apply appropriate chemicals, rinse those chemicals away, and finally extract water from the goods at the end of it all. This final extraction step determines the final moisture retention of the goods and is directly related to the G-force at which the goods were extracted: The higher the extraction force is, the lower the moisture retention. It is important to note that this process is not linear, for example, doubling the G-force won’t automatically halve the moisture retention. For convenience, I’ve included a handy graph below for some typical fabric types (click to see it full sized).

The graph shows roughly how much water is left in the goods after extract, expressed as a percentage of the original dry weight prior to washing. For example, 100 pounds of dry terry towels will hold about 98 pounds of water after being washed and extracted at 100G. Now you’ll take those still very wet towels and place them in the dryer where that 98 pounds of water will have to be evaporated. Using the handy formula in the Laundry Planning Guide, we find that 98 pounds equal about 11-3/4 gallons of retained water that must be evaporated.

Taking a look at the same chart, we can do the same calculations for the same load of towels, this time extracted at 350G. Instead of 98 pounds, we now only have to evaporate 65 pounds of water, which is about 7-3/4 gallons, or about 4 gallons less water to remove. There are some obvious benefits here:

- Less water to evaporate means less total time to dry, increasing efficiency.

- Less time to dry means less fuel consumed in the drying process, lowering direct costs.

- Less time spent tumbling in the dryer reduces wear on the goods, increasing their life.

There are also a couple of less obvious benefits:

- A given laundry can reduce total dryer capacity by 20%, meaning lower machinery investment is needed.

- For the same laundry throughput, less floor space is required.

How much is too much?

Just like your mom always told you, there can definitely be too much of this good thing. Once you extract above 400G or so, the risk of fabric damage becomes apparent. Plus, referring again to the graph, there isn’t a notable difference between 350G and 400G, only an additional 1 pound of water is removed (only an additional 1 cup of water). As G-force increases, the gains in moisture removal get smaller and smaller for each increase. These higher speeds are also difficult for the washers to achieve consistently and most manufacturers that offer these high-speed machines use various tricks to get around this very hard limitation.

Calculating Moisture Retention

Finally, it’s pretty easy to calculate moisture retention:

- Wash and promptly remove the goods from the washer after final extract. Remove a sample of 10 pieces from the middle of the pile as goods on top will tend to be a bit dryer, giving false results.

- Immediately weigh your sample of 10 pieces and record this weight as W1. Place these goods into the dryer and dry until completely dry.

- Remove the sample of 10 pieces from the dryer and weigh. Record this weight as W2.

Moisture Retention (%) = (W1 – W2) / W2

About the Author:

Al Adcock is VP of Sales and Marketing at B&C Technologies. He is an industry veteran with over 29 years of experience, working for different manufacturers in many different capacities before helping launch B&C Technologies in 2000. Adcock has played an instrumental role in the design of several machines on the market before moving to sales in 2013.

Al Adcock is VP of Sales and Marketing at B&C Technologies. He is an industry veteran with over 29 years of experience, working for different manufacturers in many different capacities before helping launch B&C Technologies in 2000. Adcock has played an instrumental role in the design of several machines on the market before moving to sales in 2013.

Based in Panama City Beach, FL, B&C Technologies is a family-owned customer-focused company that builds the highest quality laundry equipment at the most competitive prices. All B&C equipment relies on engineering-driven designs to produce machines that consistently perform and constantly produce.